You’ve spotted a gap in the market, an opportunity for a product and you’re a Start-Up waiting to happen. But how do you take that raw idea and develop it into the production-ready design that will drive your business?

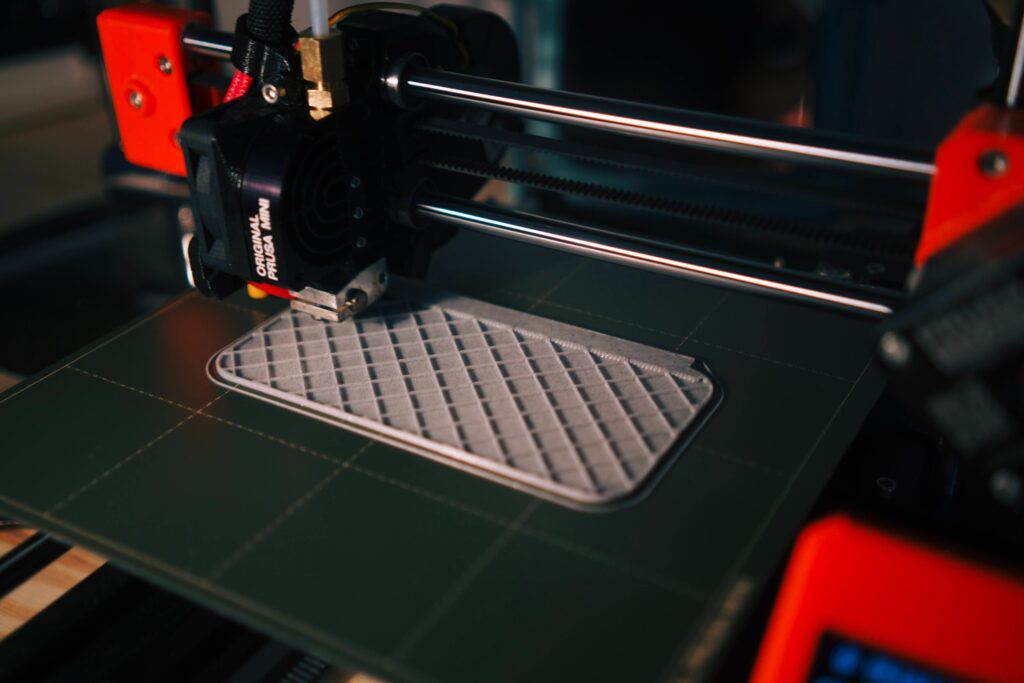

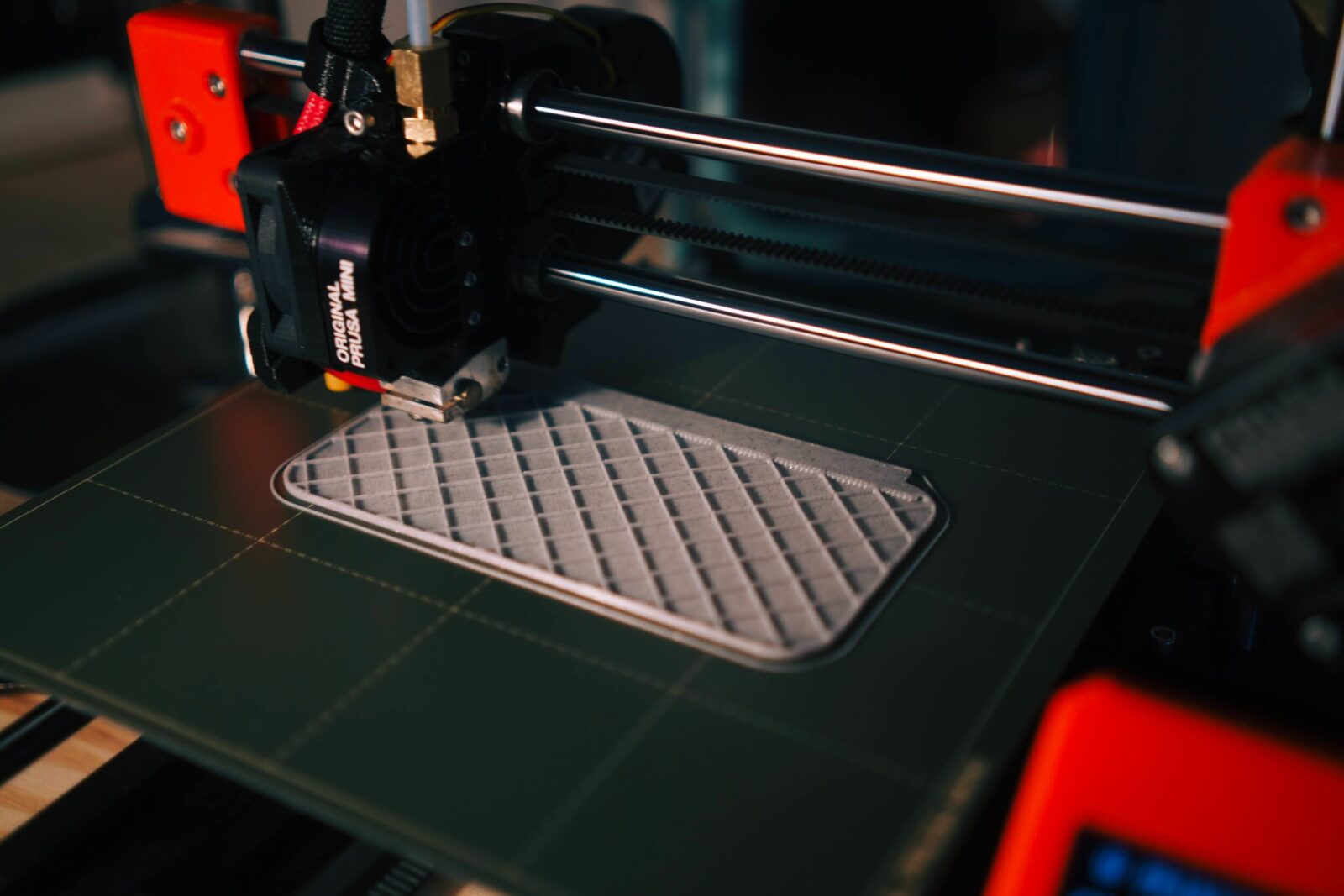

3D Printing

Well the answer isn’t easy and the road ahead looks like spaghetti junction but through this Blog Series I’m going to explain the design process and how Design By Datum can guide you through the gauntlet of Product Development.

Myself and David have been doing this for brands and businesses for the best part of the last 10 years and whether its sports gear, medical devices or consumer electronics each project we have worked on followed roughly the same structure.

I’ll start with an overview today and then a deep dive into each stage with separate blog posts over the coming months.

Feasibility: Checking Strength of your idea.

You need to know if the gap in market you have identified is there because no-one else has spotted it or because a product consumers will accept just isn’t feasible in that space? We do this through thorough research using three major tools: Competing Product analysis, Market Needs Research and a Technology audit. With the information from these three exercises we build your Product Specification and the Core Benefit Proposition of your product.

Concept Design : Idea generation, exploration and selection.

This stage can often require the most creativity but hard work put in here can save a lot of time and resources down the line. The key is being able to create a large quantity of ideas rapidly, then selecting and rejecting the good and bad ideas efficiently. Truly innovative designs never appear by chance, there’s a lot of debate around who actually said this but the mantra still holds true: “Genius is 1 percent inspiration and 99 percent perspiration.” Design By Datum will use a range of ideation, sketching and modelling techniques to produce a bespoke concept package that works for you and your project.

3D Development: Defining the features, developing details and design for manufacture.

Now we turn your selected 2D concepts into 3D CAD. This 3D Data is the most valuable asset we will create for you, it will be used to build prototypes, gather manufacturing quotes and create photorealistic renders. The model or models will be created using the principles and best design practises for a selected manufacturing method and once it has undergone the Prototype and Test stage a modified version of this CAD will be used in Production.

Prototype, Test and Refinement: Testing the design against its requirements.

There are many different ways to create prototypes from your 3D data including 3D printing, CNC Machining and Casting . Often a combination of several methods will be used to create your functional prototype. We then put your prototype through its paces and after user trials, physical tests and simulations, we analyse the data and create design recommendations. We work through a cycle of refinement and testing based on product performance and your feedback until we meet the design specification and are ready to proceed to the Final Stage.

Pre Production: Getting you and your product ready for mass production.

We create engineering drawings, assembly instructions and any other documentation in order to liaise with trusted suppliers and manufacturers. Design By Datum have first hand experience with UK, European and Far East manufacturing and we help create a production plan best suited to you and your business.